In 2005 nrca participated in a limited testing program that showed a majority of polyisocyanurate insulation samples tested one to four years after being manufactured had actual r values less than their lttr values.

Polyisocyanurate insulation r value aged.

Csi2eye 6 astm c1303 lttr is intended to represent the r values of specimens tested ajer five years of aging when stored in a controlled laboratory environment.

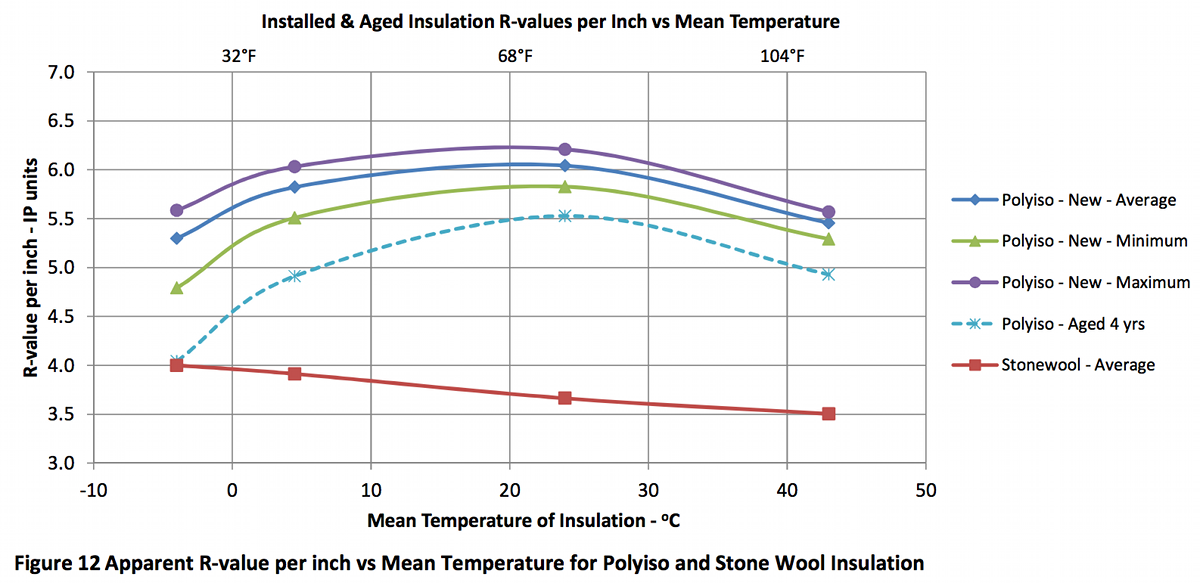

The results also are somewhat lower than the results at 25 f 40 f 75 f and 110 f mean test tem peratures from nrca s 2009 testing.

As polyisocyanurate insulation ages further its r value decreases at a slower rate until the gas con.

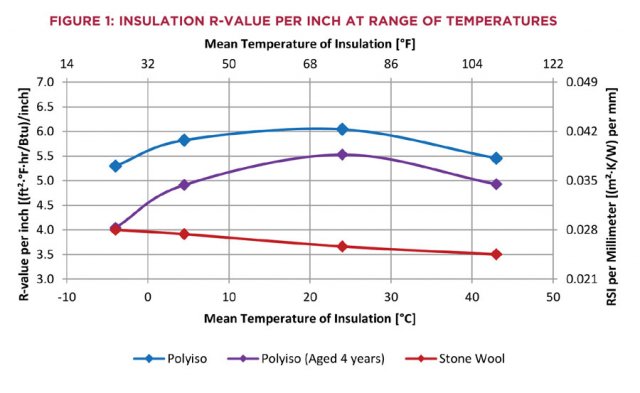

Because of this phenomenon the r value of polyisocyanurate insulation is not constant.

The r value of polyisocyanurate decreases as some of the gasses in the pores from the manufacturing process diffuse out and are replaced with air.

During late 2014 nrca conducted additional limited r value testing of polyisocyanurate insulation and found r values lower than the current lttr values.

Long term performance and aged r value of polyisocyanurate insulaon march 16 2017 csi chicago chapter.

Mates r value after five years of aging in controlled laboratory conditions.

The information on this page is based on data considered to be true and accurate based on periodic internal.

This five year figure corresponds closely to a predicted.

In 2009 nrca conducted r value testing at various.

2 stated thermal resistance values are based upon conditioning requirements and test methodology found in astm c1289 and astm c518 for foil faced polyisocyanurate insulation.

Its r value is highest soon after man ufacturing and decreases at a relatively significant rate during the earliest portion of its service life.

See also material data sheet msds 1511 or msds 1911.

As part of that standard the products must meet r value requirements presented as long term thermal resistance lttr.

The in service aged results were compared with the same insulation tested when it was a new material and it was determined the aged insulation had a significantly reduced r value up to 25 at low mean temperatures compared with the new insulation demonstrating the effects of the initial aging on the material s performance.

1 when joints penetrations detailed appropriately.

As foam ages over time air and blowing agents diffuse in and out of the foam structure resulting in reduced r value.

Polyiso has a high r value per inch compared to other insulation products.

Many but not all foam insulations or settle e g.

Polyiso is unique in that the r value increases with the thickness of the foam so three inches of polyiso has a higher r value per inch than two inches.